Precision Fasteners & Custom CNC Components

Dowel Pins, Keys, Retaining Rings, Screws

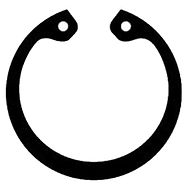

RTW Internal Retaining Ring

(5000 Series Internal Retaining Rings | ANSI Standard)

The 5100 Series is the American standard (ASME / ANSI) R-Type Internal Retaining Ring, designed to be installed in bore grooves of mechanical components. It restricts the axial movement of bearings, washers, or other parts, ensuring secure assembly while allowing repeated installation and removal.

Its design features a double-hole structure, which enables quick installation and removal using dedicated internal circlip pliers. Widely applied in European and American imported equipment as well as heavy-duty machinery.

Product Features

-

Standard Compliance: Manufactured to ASME/ANSI specifications, aligned with the American Ring 5100 series

-

Installation: Secured inside bore grooves to retain bearings, washers, or internal assemblies

-

Precision Fit: Consistent tolerances and reliable engagement, suitable for high-load or high-speed mechanisms

-

Material Options:

▸ S50C (Carbon Steel) – Black oxide coating for rust resistance and durability

▸ SUS420 (Stainless Steel) – Heat-treatable, suitable for corrosive or high-strength environments -

Size Range: Inch sizes from 0.125” to 10”

Applications

-

U.S. machinery maintenance and OEM replacement parts

-

Internal thrust retention in imported equipment

-

Bearing stop or sleeve limiting for motors and rotary systems

-

Anti-loosening components in automated assembly units

Customization & Notes

-

Supports special sizes, small-batch prototyping, and high-volume production

-

Dimensional differences exist between 5100, JIS B 2804, and DIN 472 standards — please confirm compatibility before ordering

-

Assistance available for cross-referencing external codes or drawings – samples welcome for review